Roll to roll Inspection & Sheet Inspection

The inspection machine operates independently, equipped with a high-resolution CCD vision camera. It features inspection software that is easy to configure, facilitating efficient inspection processes.

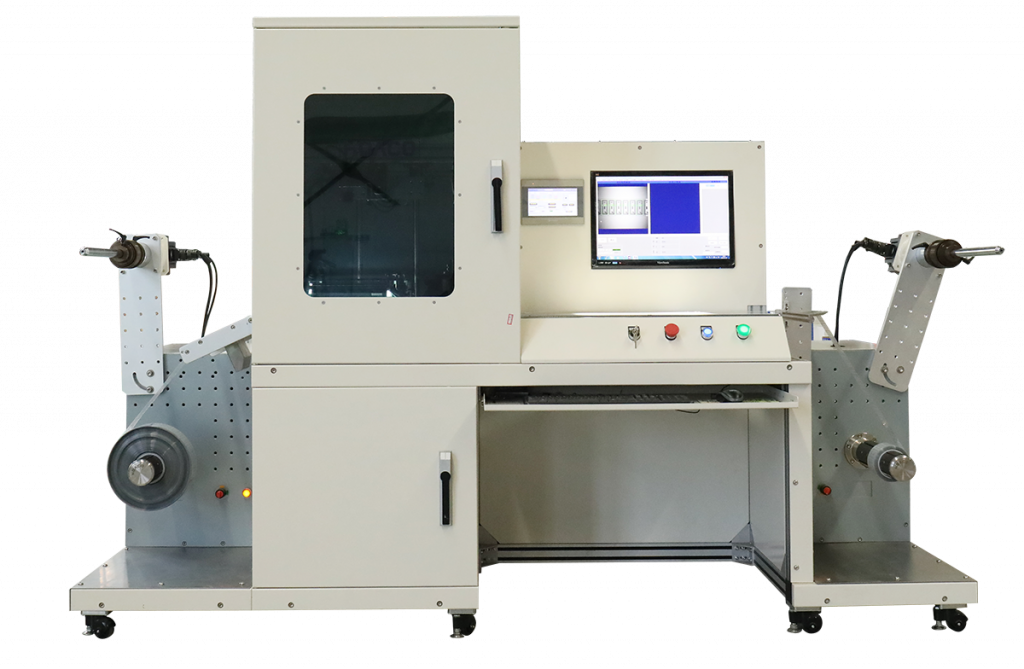

Contact UsRoll to Roll Inspection Machine

Vision inspection machine is a standalone CCD-camera-based visual testing system used for offline product dimension measurement, appearance check and inspection for defects for products in rolls. The machine can run up to 20m/meters and achieve precision up to 0.01mm. Its camera’s field of view can simultaneously detect and inspect up to 150 product units. Inspection type includes product count, impurities, stains, bubbles, unevenness, missing units, blue films, etc. The machine can also be ordered to custom-made dimension, capability and appearance.

- Machine configuration on demand

-

Main features of the Roll to Roll Inspection

Fully customized to our customers’ requirements

Our roll to roll inspection machine uses contactless vision technology for inspection purposes, eliminating the need for physical contact. It offers a wide color spectrum, including infrared imaging, to capture detailed visual information.

3D camera

Features a fully adjustable 3-dimensional camera bracket, allowing for precise positioning and optimal viewing angles.

Warning Mechanism

Incorporates a machine warning/stop mechanism that activates when dimensions are out-of-specification, ensuring product quality.

Versatility

Provides versatile ring-type or bar-type lighting arrangements from various angles, enabling effective illumination.

Quality Control

It can integrate a defects management system that can automatically print black marks, label stickers, or reject defective parts, streamlining quality control processes.

-

Explore how the Roll to Roll Inspections works

Do not miss the two demo videos

-

Sheet Inspection Machine

Specifically designed for sheet inspection process

Sheet inspection machine is a standalone CCD-camera-based visual testing system used for offline product dimension measurement, appearance check and inspection for defects for products in rolls. Inspection type includes product count, impurities, stains, bubbles, unevenness, missing units, blue films, etc. The machine can also be ordered to custom-made dimension, capability and appearance.

High Resolution

High-resolution vision-based inspection system

Continuous operation

Dual incoming sheets holder for uninterrupted machine operation

Dual camera

Dual camera to examine products from top and bottom.

Automatic System

Automatic FG binning according to inspection criteria.

-

Sheet Inspection Machine

Discover how it works

- Pick Up: Incoming sheets in stacks placed into holders.

- Turntable: Rotating turntable moves sheet into vision camera’s field of view.

- Image Capture: camera captures a clear snapshot for image analysis.

- Pass/Fail Binning: Pass/Fail products picked and placed into designated bins.

Play Video

- Title

Subtitle

- Pick Up: Incoming sheets in stacks placed into holders.

- Turntable: Rotating turntable moves sheet into vision camera’s field of view.

- Image Capture: camera captures a clear snapshot for image analysis.

- Pass/Fail Binning: Pass/Fail products picked and placed into designated bins.

Play Video

- Contact us

Request us for information about our Machinery or Tooling:

Our flagship high-precision multi-stations Rotary Die Cutting (RDC) machines have served manufacturing customers with excellence in diverse industries. Today, HOACO is the unrivaled top supplier of rotary die cutting machines overseas.

General Info

Machinery

Tooling

General Info

Send us a message

Machinery

Request us for Machine info

Tooling