RotoMEA

Explore how Hoaco empowers the realization of your objectives through the implementation of IoT solutions, including the utilization of RFID converting machines.

Contact UsPrimary Application of RFID Converting Machine

Those are the layers of a typical RFID Label:

- Release Liner

- Bottom Adhesive

- RFID Inlay (Antenna + Chip)

- Label Material (Blank or Printed)

- (Optional) Protective Coating

- Explore all our machine models

Your product requirement defines our machine configuration

- Flagship RFID Labels Machine

- Rotary Cutting Machine for RFID Labels

- RFID Labels Inspection Machine

- Machine configuration on demand

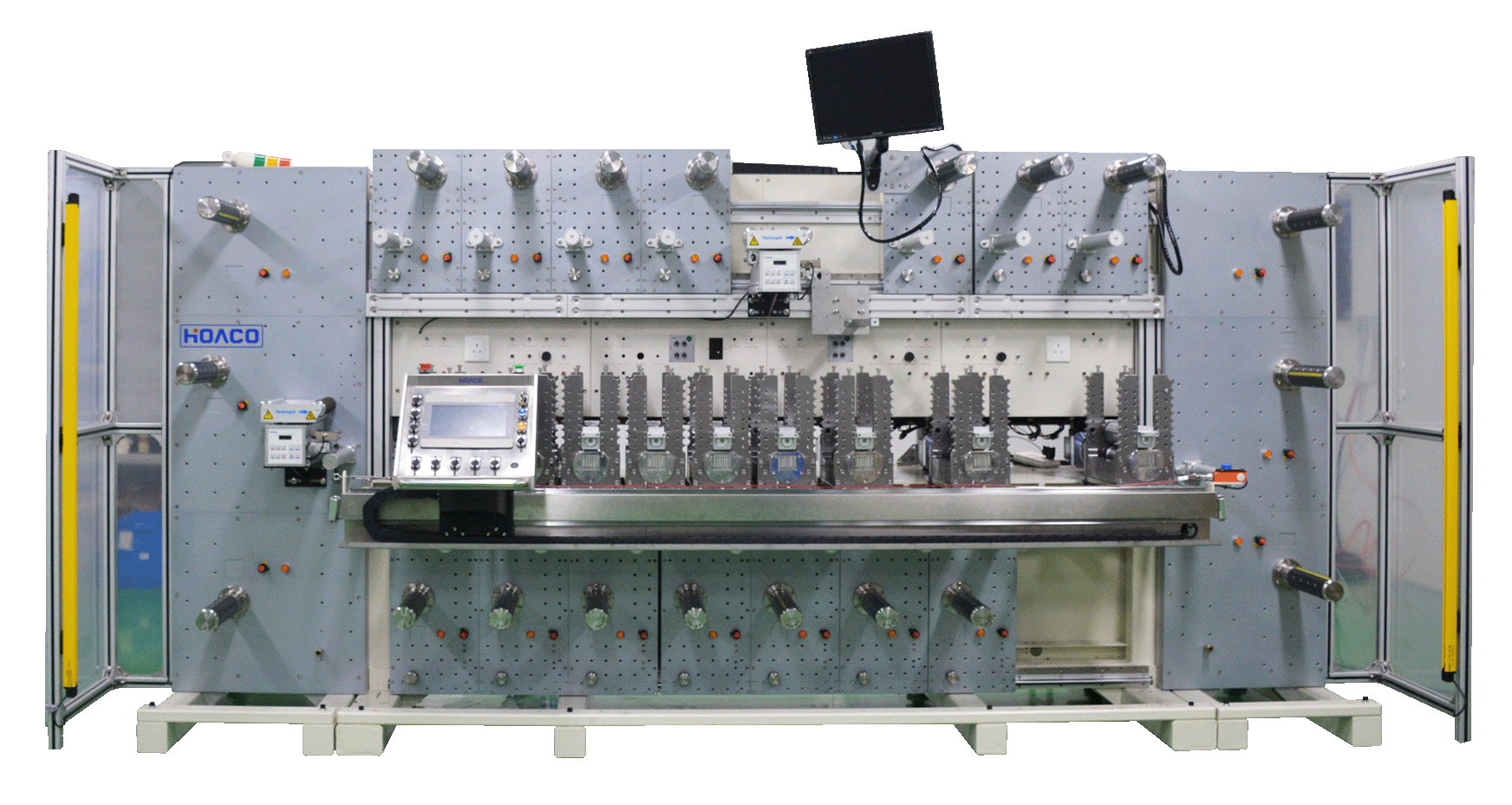

- Flagship RFID Labels Machine

A specialized RFID converting machine designed to achieve optimal cost savings

It incorporates a vacuum-based asynchronous inlay cut-n-transfer mechanism, resulting in savings on process tapes and tooling expenses. Includes multiple web guides to ensure enhanced precision. It is capable of utilizing solid or flexible dies for cutting label outlines. Hoaco’s RFID converting machine offers the flexibility of providing FG in rolls, perforated form, or sheets. Additionally, it offers optional functionalities such as inline label reading, CCD vision inspection, and defect marking.

Inline Adhesive Coating

Inline adhesive coating that saves liner cost of raw materials

Inlay Cut-n-Transfer

This process process involves the use of an innovative technique to transfer and cut RFID inlays.

Large Roll Support

The RFID machine provides extensive support for handling large rolls to allow to work on a larger scale.

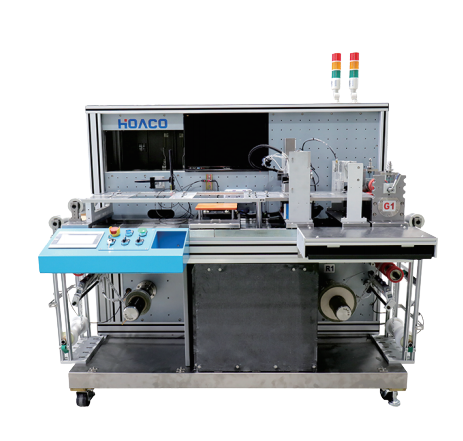

- Rotary Cutting Machine for RFID Labels

The Standard RDC for maximum versatility and precision

This model of RFID machine offers seamless handling of complex RFID labels comprising more than four layers. It incorporates a vacuum-based asynchronous inlay cut-n-transfer mechanism, resulting in savings on process tapes and tooling costs. Additionally, the machine provides optional functionalities such as inline label reading, CCD vision inspection, and defect marking for enhanced quality control.

Inline RFID Reader

Connected to a single RFID controller, multiple RFID readers can be positioned optimally to perform inline RFID functional checks for optimal process control and maximize yield.

CCD Vision Inspection

Triggered by proximity or mark sensor, high-end CCD cameras captures a high-resolution motion image for visual analysis of dimensional measurement, leftover wastes, stains or misalignment.

Inline Defect Marking

In the event of defective parts detected by either CCD or RFID reader, inkjet printers can be triggered to print black marks on the defects for easy quality control and analysis before shipment.

Inlay Cut-n-Transfer

Inlay cut-n-transfer can be realized through async lamination or vacuum-based cut-n-transfer. The former requires supporting process tapes but delivers ultimate lamination precision up to ±0.2mm. The latter saves process tapes and offers reasonable precision tolerence up to ±0.5mm.

- RFID Inspection Machine

Subtitle

The RFID Inspection machine ensures a comprehensive quality assurance process by conducting a 100% functional inspection of RFID tags before shipment. In the event of detecting defective labels, the machine automatically halts its operation, allowing for easy manual replacement and re-testing.

Caract 1

Mechanical precision with Sun (550) and Planetary gears

Caract 2

Ultra-high master-slave cutting alignment precision.

Caract 3

Each satellite station can be used for cutting or lamination.

Caract 4

Unified machine frame with standard stations for ultimate integration and precision

- The best Rotary Die Cutting Machines

Take a tour of our facilities

We are proud to offer the best tooling for die cutting machinery. With our technology and expert team.

Play Video

- Contact us

Request us for information about our Machines or Tooling:

Our flagship high-precision multi-stations Rotary Die Cutting (RDC) machines have served manufacturing customers with excellence in diverse industries. Today, HOACO is the unrivaled top supplier of rotary die cutting machines domestically in China, while gaining customers rapidly overseas.

General Info

Machines

Tooling

General Info

Send us a message

Machines

Request us for Machine info

Tooling

Request us for Tooling info

Manage consent

To offer the best experiences, we use technologies such as cookies to store and/or access device information. Consent to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Failure to consent, or withdrawal of consent, may adversely affect certain features and functions.

Functional Always active

Storage or technical access is strictly necessary for the legitimate purpose of allowing the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. .

Preferencias

El almacenamiento o acceso técnico es necesario para la finalidad legítima de almacenar preferencias no solicitadas por el abonado o usuario.

Statistics

El almacenamiento o acceso técnico que es utilizado exclusivamente con fines estadísticos.

Storage or technical access that is used exclusively for anonymous statistical purposes. Without a requirement, voluntary compliance by your Internet service provider, or additional records from a third party, information stored or retrieved solely for this purpose cannot be used to identify you.

Marketing

Storage or technical access is necessary to create user profiles to send advertising, or to track the user on a website or several websites for similar marketing purposes.

| Technical Specifications | |

|---|---|

| Speed | Up to 70m/min |

| Precision | ≤ ± 1mm |

| Dimension | L4500 x D1700 x H2400 mm |

| Weight | 2.8 Ton |

| Rated Voltage & Power | 3Phase 380Volts, 30kW |

| # of Layers | 3 or 4 |

| Top Label layer | Blank or Printed Label |

| Bottom Liner Layer | Blank or Printed Label |

| Cutting Precision | ≤ ± 0.3mm |

| Lamination Precision | ≤ ± 0.5mm |

| Max Roll Diameter | 600mm |

| Max Roll Weight | 30kg |

Play Video

| Technical Specifications | |

|---|---|

| Speed | Up to 30m/min |

| Dimension | L5200 x D1670 x H2470 mm |

| Weight | 5 Ton |

| Rated Voltage & Power | 3Phase 380Volts, 42kW |

| # of Layers | 3-6 |

| Top Label layer | Blank or Printed Label |

| Bottom Liner Layer | Blank or Printed Label |

| Cutting Precision | ≤ ± 0.05mm |

| Lamination Precision | ≤ ± 0.15mm |

| Max Roll Diameter | 500mm |

| Max Roll Weight | 25kg |

Play Video

| Technical Specifications | |

|---|---|

| Speed | Up to 300 labels/min |

| Dimension | L2300 x D1300 x H1700 mm |

| Weight | 0.8 Ton |

| Rated Voltage & Power | Single Phase 380Volts, 6kW |

| RFID Reader Interface | USB or RS232 |

| Defect Marking | Thermal Printer |

| Max Roll Diameter | 600mm |

Play Video