The best Rotary Die Cutting Machines

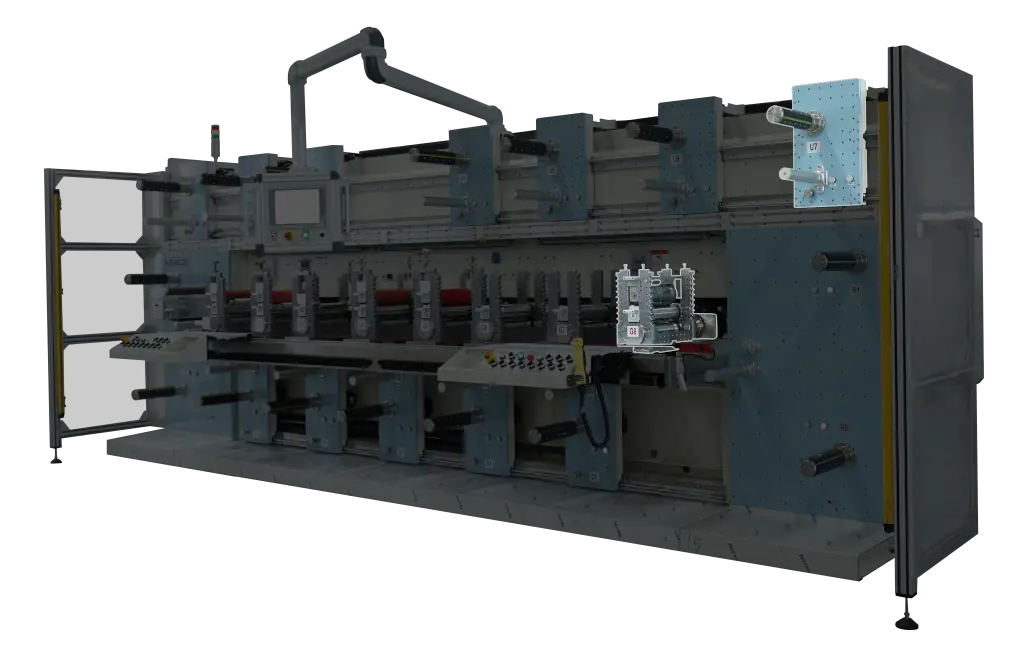

HOACO machines are the preferred solutions for manufacturer multilayered products, which enables die cutting, converting, laminating, CCD registration & inspection in a single pass.

Contact UsOur Machines

Rotary Die Cutting machines are widely used in many fields of applications, especially in electronics, medical & cosmetics, automobile, labels & printing industry. It can accommodate materials of different density, thickness and composition based on the requirements of your application.

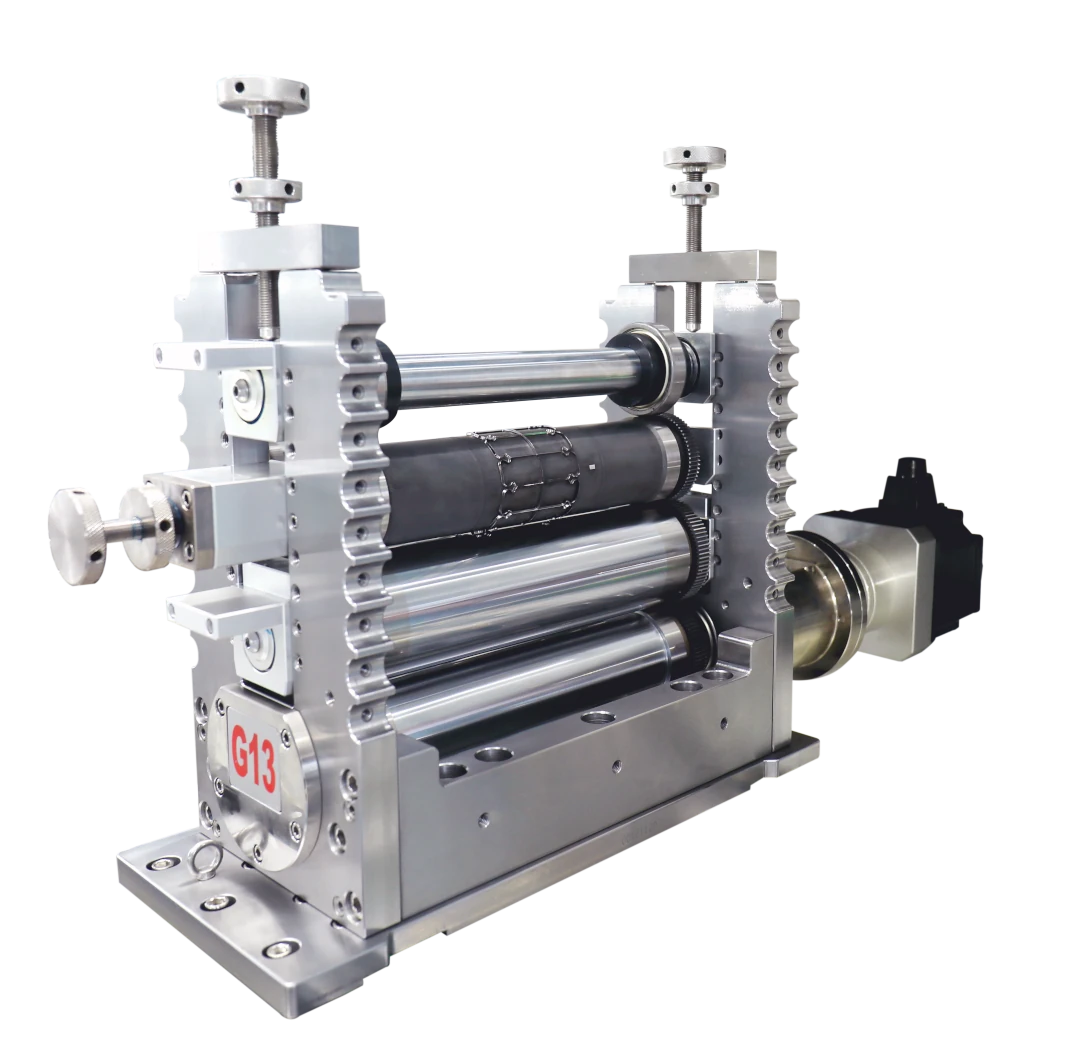

Die Set Station

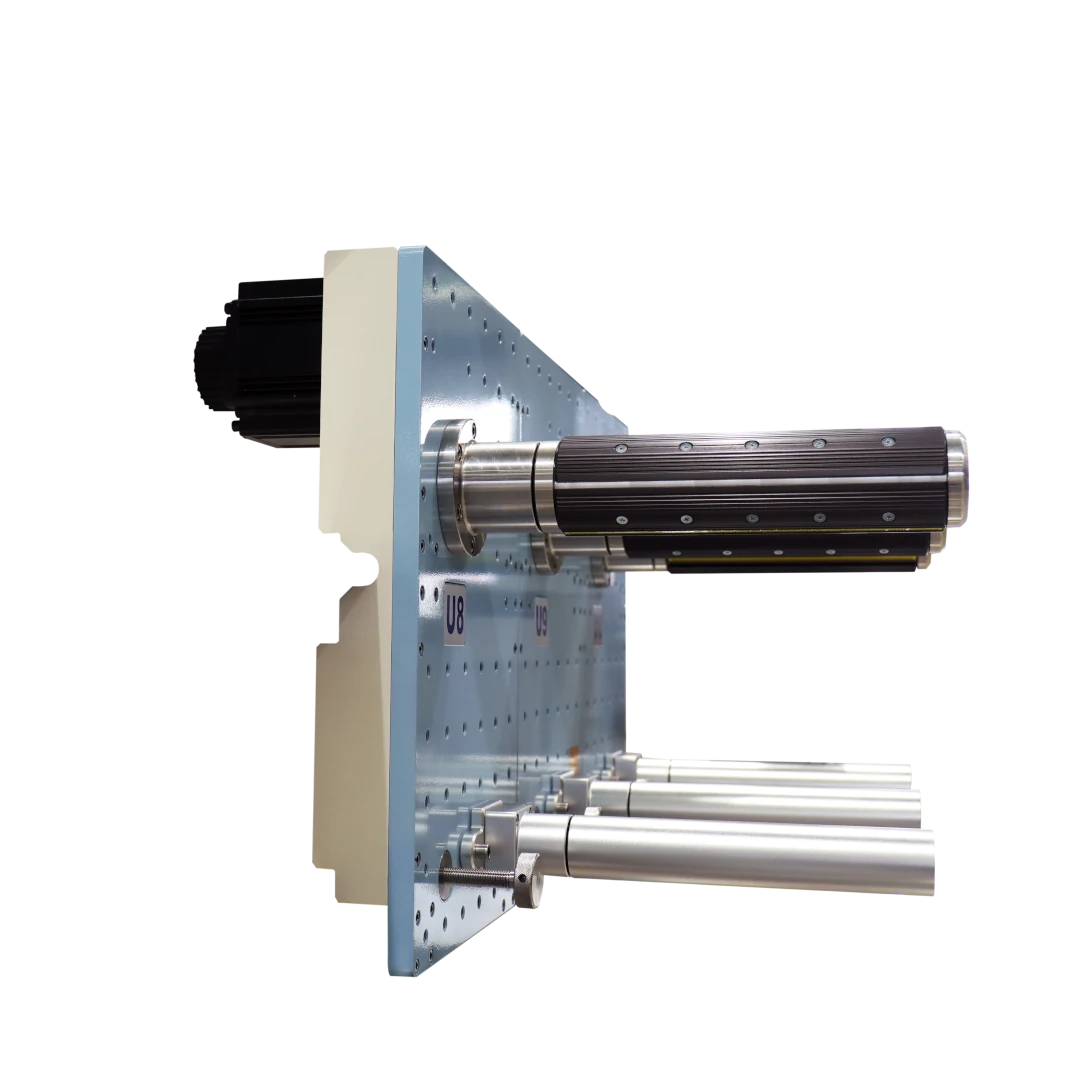

UnWind/ReWind

Island Placement

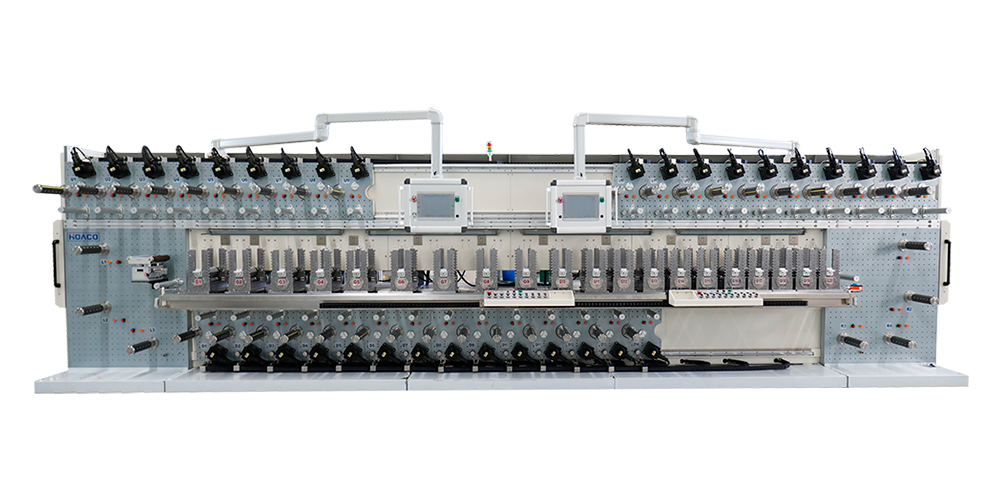

Dual System

-

How to achieve the tightest tolerances

Highlights of our Rotary Die Cutting Machines

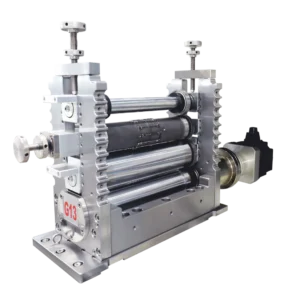

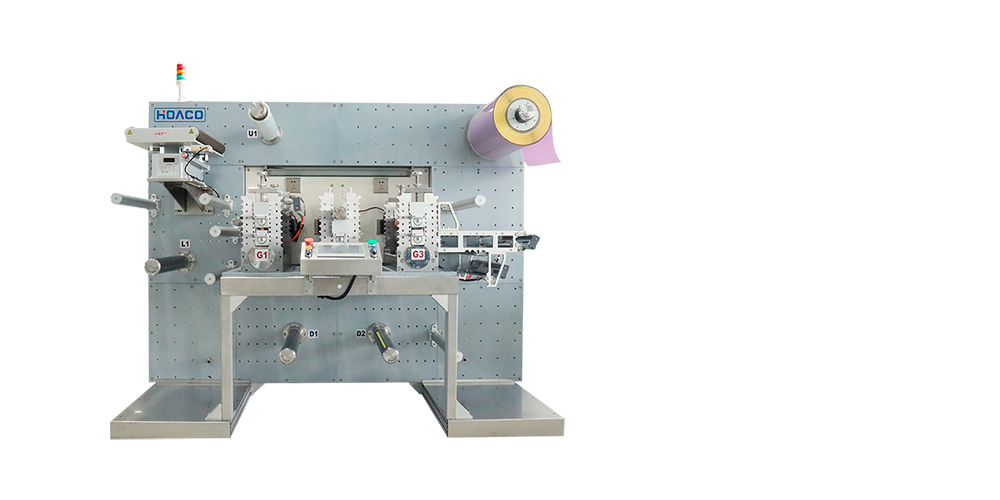

1. Die Set Station

- Multi-functional: All the processes including Converting, Laminating, CCD Alignment, Inline Printing, Rotary Die Cutting, and Laser Cutting are accomplished within this module.

- Movable: Our machines offer unparalleled flexibility in process design and material placement, thanks to their ability to accommodate 3 to 30 movable stations.

- Web Widht: Our rotary die cutting machines come with a standard web width of 250mm or 350mm, while custom-built machines can support web widht up to 750mm.

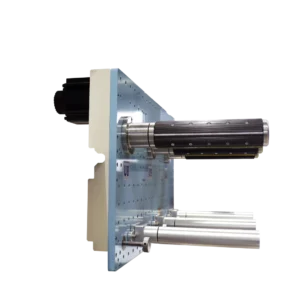

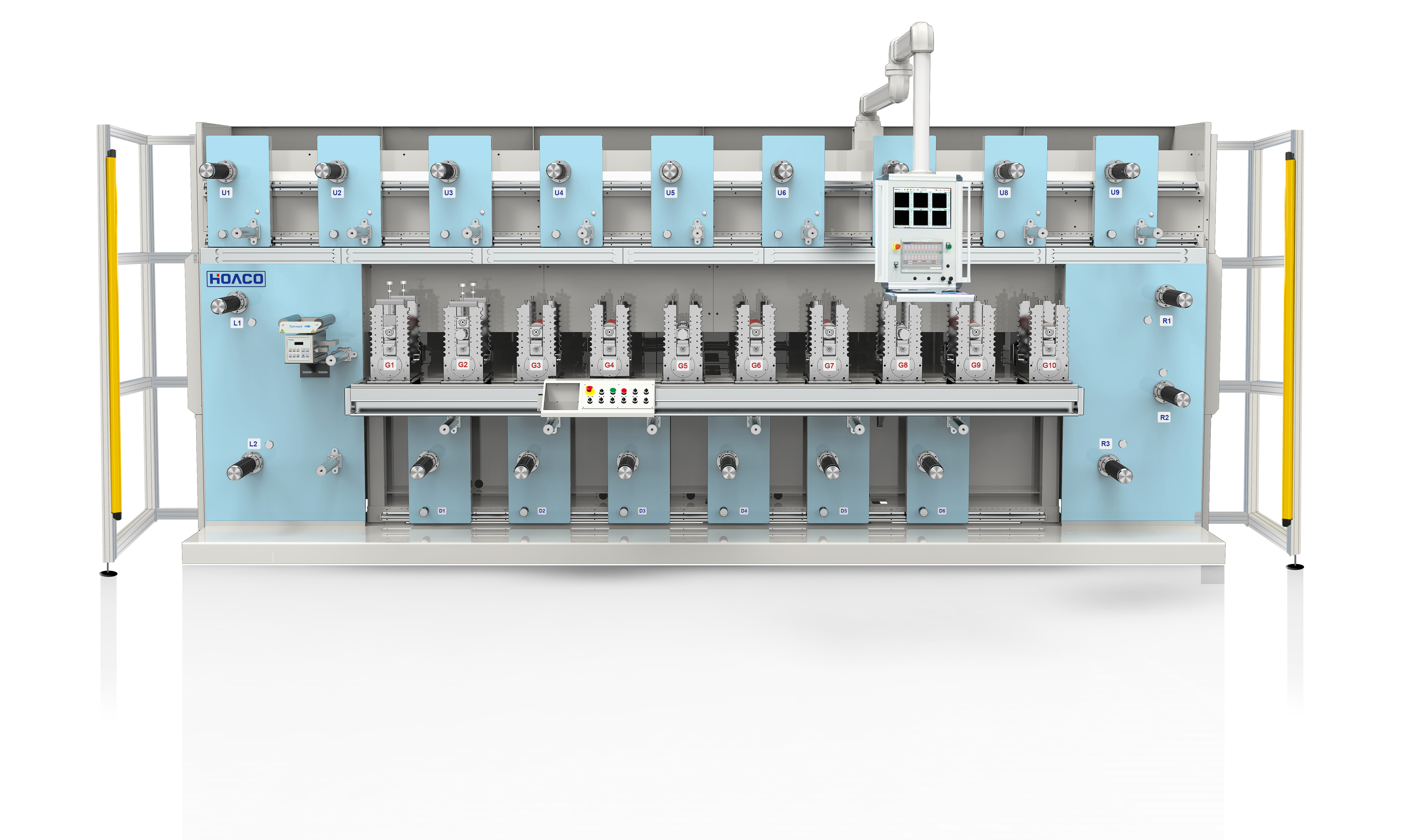

2. Unwind / Rewind

- Adjustable: Adjustable unwind/rewind stations enable extreme flexibility in material placement, tension control and quick changeover.

- Tension control: To reach high precision, the tension of each material must be very stable. Through air shafts driven by independent servomotors, material tensions, with values set through HMI interface, can maintain high stability, regardless of speed and roll diameter.

- Autoalarm: In all our Rotary Die Cutting Machines an auto alarm could be adjusted by setting minimal roll diameter before materials.

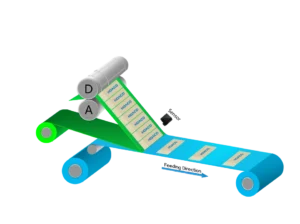

3. Island Placement

Island placement refers to the technique of starting and stoping a secondary web in order to place a die-cut part onto a primary web at a larger repeat. This method is mainly used to:

- Minimize material waste

- Place a smaller part on a larger part at an exact location

- Insert an RFID/NFC inlay on a label or sandwiched into a booklet label.

- Placing a die cut part multiple times at different repeat interval on a larger aprt.

4. Dual System

Any Rotary Die Cutting Station in a single machine can be independently assigned to either System 1 or System 2 – Dual systems, which can be configured to manufacture two different products, operated by two operators at the same time without any dependence.

- Buy one machine, get two systems

- Ultimate simplicity & flexibility

- Improve machine OEE for simple products

- Reduce factory footprint

-

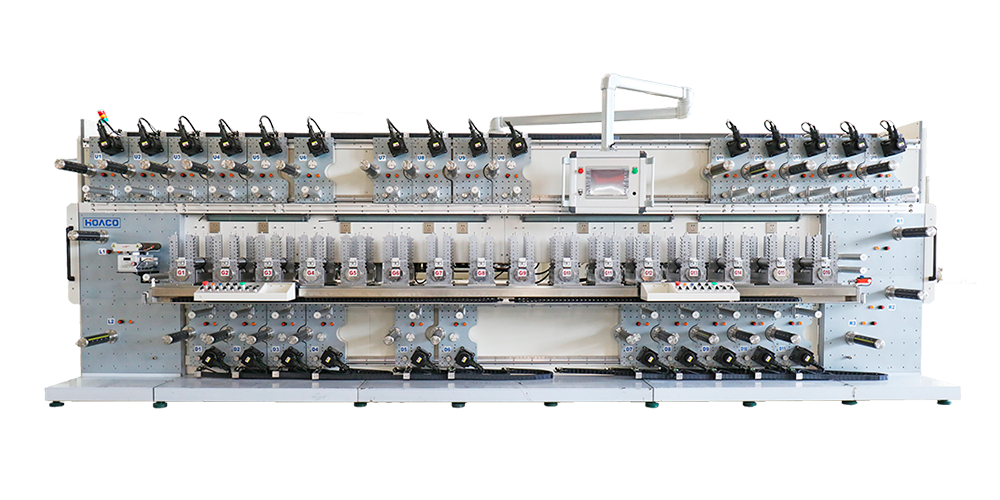

Explore all our machine models

Your product requirement defines our machine configuration

- 30 Stations

- 20 Stations

- 16 Stations

- 3 Stations

Available from 3 to 32 adjustable stations, our rotary die cutting machines enable ultimate flexibility in process design and material placement. Each station is fully capable of handling multiple layers of kiss cutting, through cutting or lamination.

Either if your project is simple or complex, we have a Rotary Die Cutting machine for your company.

-

Machine configuration on demand

-

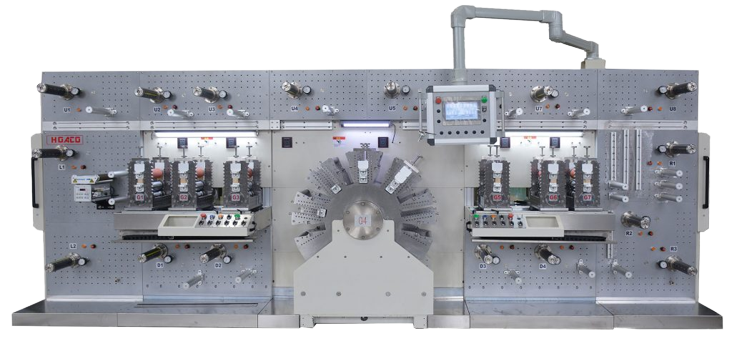

Discover the Satellite Model

The most precise Rotary Die Cutting Machine in the market

Is designed to achieve ultra-high precision up to ±0.05mm, satellite-type RDC station leverages mechanical sun-planetary gears to make it possible to cut extremely thin dimensions with high precision.

Precision

Mechanical precision with Sun (550) and Planetary gears

Alignment

Ultra-high master-slave cutting alignment precision.

Versatility

Each satellite station can be used for cutting or lamination.

Integration

Unified machine frame with standard stations for ultimate integration and precision

-

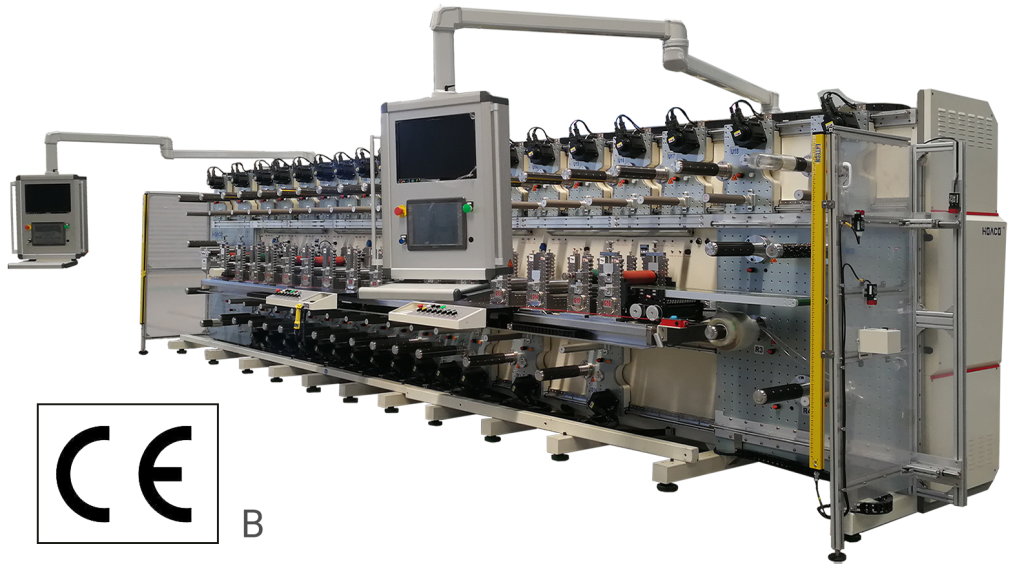

All our Rotary Die Cutting Machines are CE-Certified

Designed specially for safety and CE compliance

- Designed for functionality and price competitiveness

- More focus on ease-of-use and productivity

- Meets basic CE safety Standards

Safety Courtin

Emergency Stop button

- Built with 100% CE-Certified components

- More steps to operate but safety first

- Meets generic CE safety Standards

-

The best Rotary Die Cutting Machines

Take a tour of our facilities

We are proud to offer the best tooling for die cutting machinery. With our technology and expert team.

Play Video

-

Reviews

-

Contact us

Request us for information about our Machines or Tooling:

Our flagship high-precision multi-stations Rotary Die Cutting (RDC) machines have served manufacturing customers with excellence in diverse industries. Today, HOACO is the unrivaled top supplier of rotary die cutting machines overseas.

General Info

Machinery

Tooling

General Info

Send us a message

Machinery

Request us for Machine info

Tooling